About

_

asa

Today, a single pharmaceutical drug often crosses three continents during its lengthy production process before reaching the patient. What if we could shorten this process, simplifying the supply chain, increasing efficiency and reducing waste?

To shorten this process, we invest in two solutions:

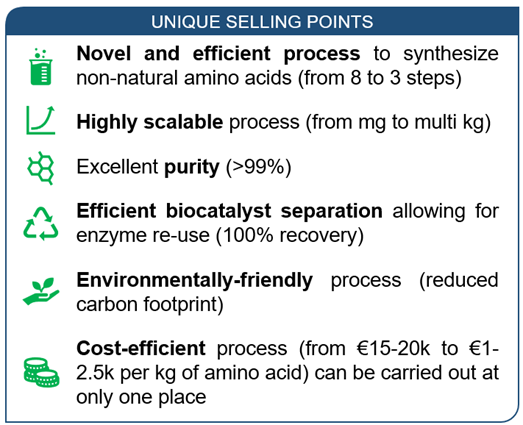

– Reducing the downstream processing (DSP) between steps: DSP involves labour-intensive steps such as isolation, purification, packaging and transportation of products. To do so, we propose the use of flow chemistry. By integrating different steps in a continuous process via the usage of sustainable enzyme carriers which allow for immobilization of enzymes, the production can be executed more efficiently and sustainable flow.

– Introducing complex chemical modifications in a single step: most pharmaceutical drugs are complex molecules which require highly regulated and precise synthetic steps. These can be facilitated by using enzymes, which are specific to a certain type of reaction and act as catalysts. In our project, we investigate new enzymes as catalysts in chemical reactions, in order to decrease the number of steps required to obtain the intermediate products, and eventually, final drug products.

The CassaFLOW innovative consortium has started to address this challenge. We are composed of experts from European research organisations and promising SMEs, supported by the European Innovation Council. The experts from Delft University of Technology (Prof. Ulf Hanefeld), Eindhoven University of Technology (Prof. Jan van Hest) and Bielefeld University (Prof. Harald Gröger) have successfully worked together to develop the innovative reaction telescoping and flow chemistry ONEFLOW technology, a key element which cassaFLOW will build upon. Two experienced industrial partners, Chiralvision (Managing Director Rob Schoevaart) and SpinChem (CEO Emil Byström) will contribute with their expertise in enzyme immobilization, sustainable carrier materials and fine chemicals (Chiralvision) and engineering for intensification of biocatalytic processes (SpinChem).

Our consortium is further advised by experts from several industries, such as Bachem, Evonik, BASF, Symeres, Jiuzhou Pharmaceutical and GSK, ensuring a strong basis in market development in the peptide, biocatalysis and pharmaceutical fields.